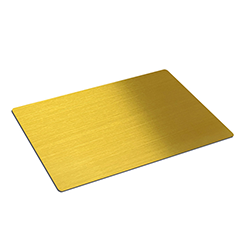

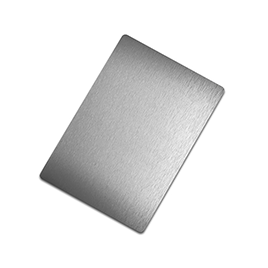

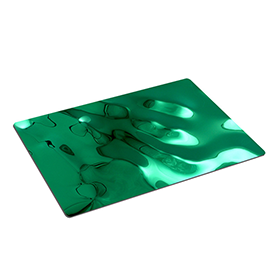

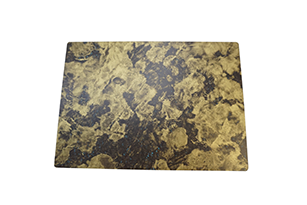

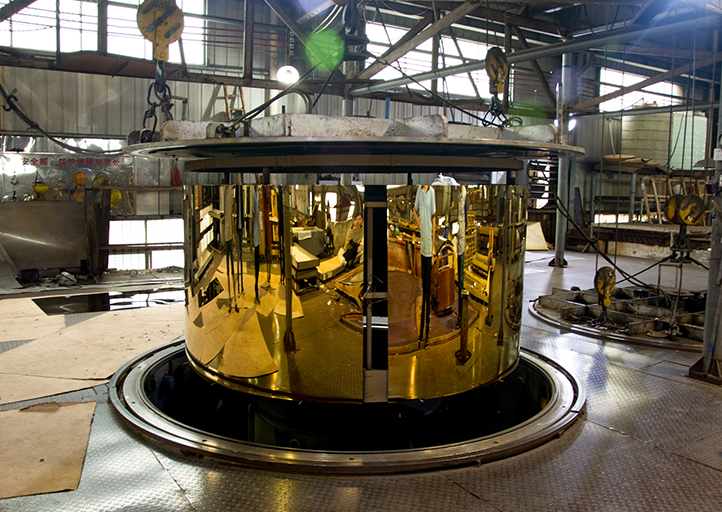

Mirror stainless steel plate is a polishing device that uses grinding fluid to polish the surface of stainless steel 2B plate, making its surface flat and with clear brightness like a mirror. Due to its superior presentation of images and reflection of light, mirrors are generally used for decoration and customization of colors in elevator doors, cars, and some high-end places. The regular size of this product is 1219mm * 2438mm. We will no longer worry about the size restrictions of your project layout, and the color and style also support personalized size. We do our best to meet the needs of every buyer.

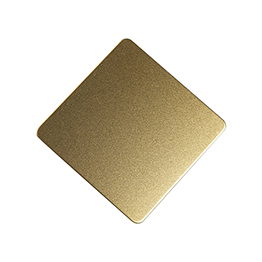

Pvd (colored finish) – Simply called Physical vapor deposition (PVD) – identifies a number of vacuum deposition processes which is able to be used to create a thin coatings.PVD is described as a process to produce a metal vapor that can be deposited on electrically conductive materials as a thin highly adhered pure metal or alloy coating.It is actually a vacuum coating process that creates a amazing decorative and functional finish.PVD uses titanium nitride, which provides an extremely durable coating.PVD coatings are more resistant to corrosion from sweat and regular wear than normal stainless steel finish.The typical thickness of our PVD coatings is 2-5 microns. We can also support two color in one sheet.

| 序列号 | 中国

CHINA GB1220 |

日本

JAPAN JIS |

美国

USA |

英国

UK BS970 BS1449 |

德国

GERMANY DIN17440 DIN17224 |

法国

FRANCE NFA35-572 NFA35-576-582 NFA35-584 |

|

| ANSI | ASTM | ||||||

| 1 | 1Cr17Mn6 | SUS201 | 201-1 | S20100 | |||

| 2 | 1Cr18Mn8Ni5N | SUS202 | 202 | S20200 | 284S16 | X12CrNi177 | SZ12CN17.07 |

| 3 | 1Cr17Ni7 | SUS301 | 301 | S30100 | 301S21 | X12CrNi188 | Z10CN18.09 |

| 4 | 1Cr18Ni9 | SUS302 | 302 | S30200 | 302S25 | X5CrNi189 | Z6CN180.9 |

| 5 | OCr18Ni9 | SUS304 | 304 | S30300 | 304S15 | X2CrNi189 | Z2CN180.9 |

| 6 | O OCr19Ni10 | SUS304L | 304 | S30403 | 304S12 | Z5CN18.09A2 | |

| 7 | 2Cr23Ni13 | SUS309 | 309 | S30900 | |||

| 8 | Ocr23Ni13 | SUS309S | 309S | S30908 | |||

| 9 | Ocr25Ni20 | SUS310S | 310S | S31008 | X5CrNiMo1812 | Z6CND17.12 | |

| 10 | OCr17Ni12Mo2 | SUS316 | 316 | S3160 | 316S16 | X2CrNiMo1812 | Z2CND17.12 |

| 11 | OOCr17Ni14Mo2 | SUS316L | 316L | S31603 | 316S12 | ||

| 12 | 1Cr18Ni9Ti OCr19Ni10Ti |

SUS321 | 321 | S32100 | 321s12

321s20 |

X10CrTi189 | Z6NT18.10 |

| 13 | 1Cr17 | SUS430 | 430 | S43000 | 430S15 | X8Cr17 | Z8C17 |

| 14 | 1Cr13 | SUS410S | 410S | 430S17 | X7Cr13 | Z6C13 | |

| 15 | 2 Cr13 | SUS420J1 | 430S37 | X20Cr13 | Z20C13 | ||

| 16 | 3 Cr13 | SUS420J2 | 420 | S42000 | 430S45 | Z15CN16.02 | |

| STAINLESS STEEL COIL & SHEET | |

| 钢种Grade | 201J1,201J2,201J3,201J4,201J5,202,301,302,304,304L,316L,321,309,310S,410S,420J2,430 |

| 标准Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| 轧制工艺Technical | Hot Rolled & Cold Rolled |

| Thickness: | Hot Rolled 3.00-16.00mm & Cold rolled 0.30-3.00mm |

| Width: | 3mm-2500mm or as required |

| Length: | Stainless Steel Coil Stainless Steel Sheet 1000*2000mm & 1219*2438mm & 1500*3000mm & 1500*6000mm or as customized |

| Edge: | Mill Edge=1000/1240/1530mm & Slit Edge=1000/1219/1500mm |

| Thickness Tolearance: | According to mill requirements |

| Surface: | NO.1/2B/NO.4/HAIRLINE/6K/8K |

| Certification: | ISO9001&ISO14001 |

| Processing Service: | Bending, Welding, Decoiling, Punching, Cutting, Folding, Planer |

| Standing Inventory | 1000 tons |

| 钢 种 | 机 械 性 能 | ||||||

| KS (JIS) |

热处理条件 |

屈服强度(N/mm2 ) |

抗拉强度(N/mm2 ) |

延伸率(%) |

硬度 | ||

| HB | HRB | HV | |||||

| 301 | S | ≥205 | ≥520 | ≥40 | ≤207 | ≤95 | ≤218 |

| 301L | S | ≥215 | ≥550 | ≥45 | ≤187 | ≤90 | ≤200 |

| 304 | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 304J1 | S | ≥155 | ≥450 | ≥40 | ≤187 | ≤90 | ≤200 |

| 304L | S | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 |

| 304N1 | S | ≥275 | ≥550 | ≥35 | ≤217 | ≤95 | ≤200 |

| 304N2 | S | ≥345 | ≥690 | ≥35 | ≤248 | ≤100 | ≤260 |

| 316 | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 316L | S | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 |

| 321 | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 409L | A | ≥175 | ≥360 | ≥25 | ≤162 | ≤80 | ≤175 |

| 410L | A | ≥195 | ≥360 | ≥22 | ≤183 | ≤88 | ≤200 |

| 430 | A | ≥205 | ≥450 | ≥22 | ≤183 | ≤88 | ≤200 |

| 430J1L | A | ≥205 | ≥390 | ≥22 | ≤192 | ≤90 | ≤200 |

| 436L | A | ≥245 | ≥410 | ≥20 | ≤217 | ≤96 | ≤230 |

| 410 | A | ≥205 | ≥440 | ≥20 | ≤201 | ≤93 | ≤210 |

| 420J1 | A | ≥225 | ≥520 | ≥18 | ≤223 | ≤97 | ≤234 |

| 420J2 | A | ≥225 | ≥540 | ≥18 | ≤235 | ≤99 | ≤247 |

We have implemented strict quality control systems to ensure that our stainless steel products meet the highest standards of quality. We use only high-quality raw materials and advanced production processes to create consistently reliable and durable stainless steel products.

We understand that every customer has unique needs and preferences. We offer customization options to tailor our products to meet specific requirements, whether it's the size, finish, or other customizations. We work closely with customers to ensure that their needs are met with precision and satisfaction.

We are committed to innovating in the stainless steel field, introducing new products, technologies, and processes that improve performance, durability, and aesthetics. We invest in research and development to stay at the forefront of technology and stay ahead of the competition.

We pride ourselves on providing exceptional customer service, from initial consultation to post-sales support. Our team of experts is available to answer questions, provide guidance, and address any concerns that customers may have. We strive to build long-term relationships with our customers through exceptional service and support.

We are committed to sustainable practices in our stainless steel manufacturing processes. We prioritize environmental responsibility, using recycled materials, reducing waste, and implementing energy-efficient production methods. We aim to minimize our environmental impact while meeting the demands of our customers.