Laser cutting of stainless steel requires experienced employees to perform stable operations. Use special instruments to draw cutting drafts. Reconfigure the accuracy of machine control. Realize precise cutting

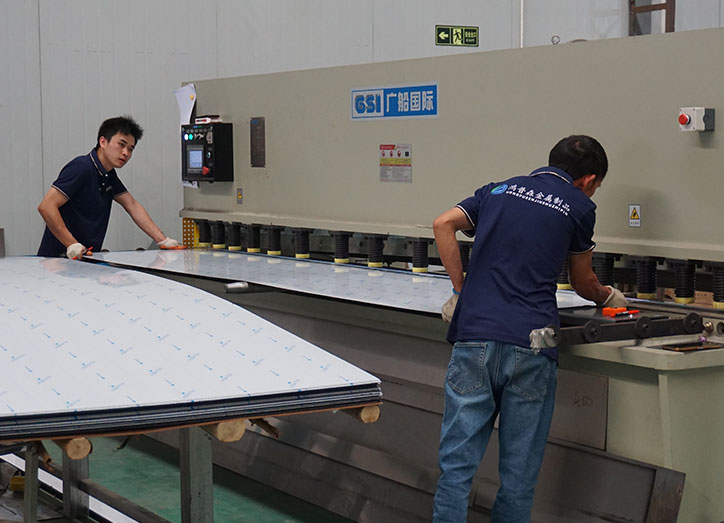

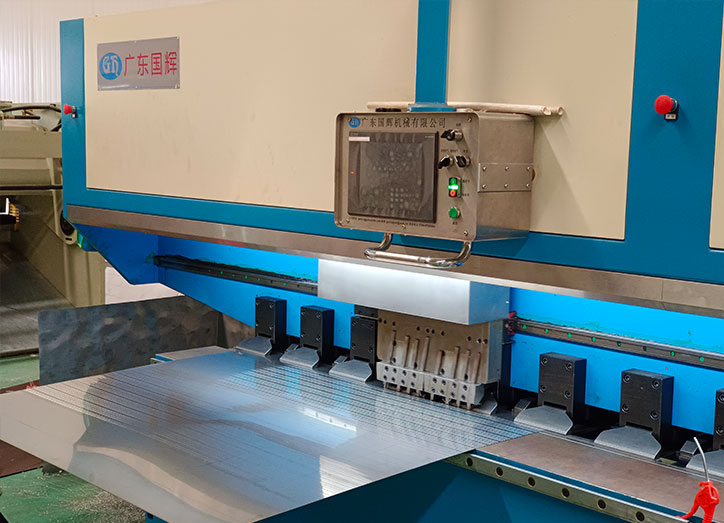

It is a machine that uses one blade to make reciprocating linear motion with respect to another blade to cut plates. By means of the moving upper blade and the fixed lower blade, a reasonable blade gap is used to apply shear force to metal plates of various thicknesses, so that the plates are broken and separated according to the required size.

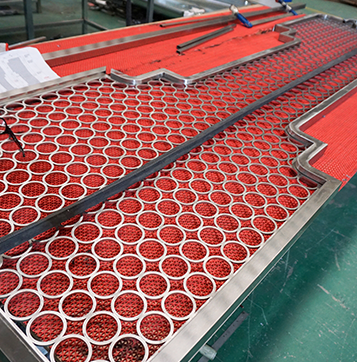

Fix the plate to be grooved on the worktable, adjust the processing starting point (origin), and use the tool rest adjusting motor to drive the tool rest to perform planing and processing on the plate to form the required "V" groove. The depth and width of the "V" can be ensured by the feed amount and different tools. Before slotting, it is necessary to program according to the number, spacing, depth and width of slotting required for slotted plates. Automatic slotting can be carried out after the programming parameters are input

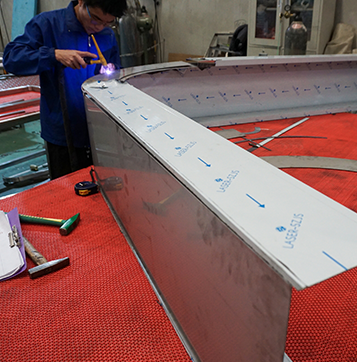

The bending and forming of stainless steel sheets are carried out on the bending machine. Place the workpiece to be formed on the bending machine, lift the brake shoe with the lifting lever, slide the workpiece to the appropriate position, and then lower the brake shoe to the workpiece to be formed. The bending and forming of metal is realized by applying force to the bending lever on the bending machine.